Sewer systems are the unseen lifelines of urban infrastructure, efficiently managing wastewater and maintaining public health. As these systems age, precise inspections are crucial to prevent failures that could cause environmental and public health crises. Multi-Sensor Inspection (MSI) technology represents a paradigm shift in how municipalities and utilities approach sewer maintenance. This article explores MSI, its technologies, and their role in maintaining robust sewer systems.

Understanding Multi-Sensor Inspection (MSI)

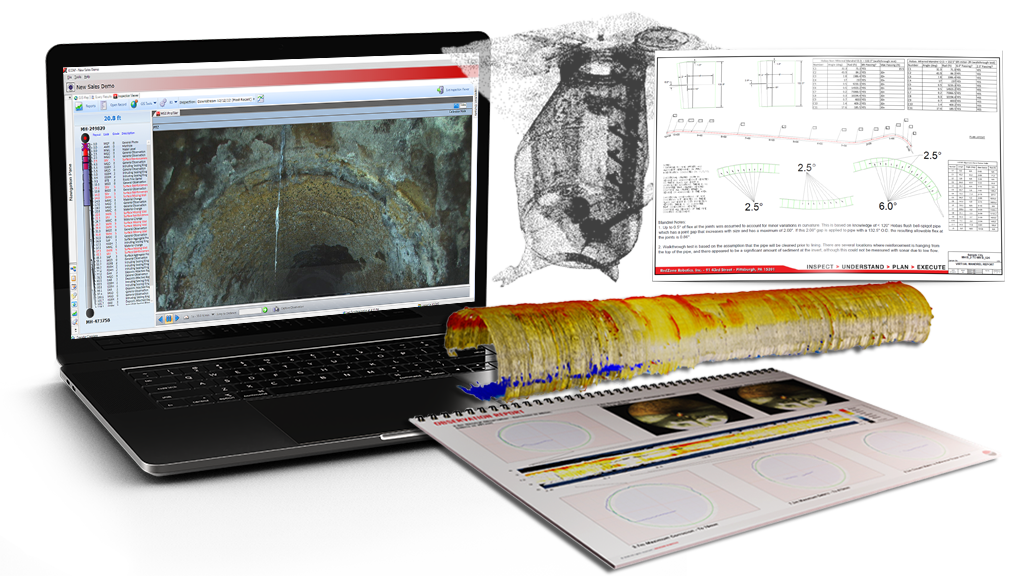

Multi-Sensor Inspection (MSI) is an integrated approach that uses various sensor technologies simultaneously to gather a detailed and comprehensive view of the internal condition of sewer pipelines. Unlike traditional methods that rely on subjective visual assessments alone, MSI provides a multi-dimensional analysis, offering a clearer, quantitative, and more accurate picture of a sewer system’s status.

Why MSI Is Important?

The significance of MSI in sewer management cannot be overstated. Traditional single-sensor inspection methods can overlook or inadequately assess potential issues such as cracks, blockages, or structural weaknesses. Further pipe conditions may limit the ability to obtain a full view of the interior of the pipe. MSI addresses these limitations by combining multiple data points to create a holistic view of the pipeline’s condition, providing insight into previously undetectable defects such as corrosion, deformation or sediment . This approach allows for:

- Enhanced Accuracy: By integrating data from various sensors, MSI reduces the likelihood of misdiagnosis and ensures more accurate assessments.

- Cost Efficiency: Early issue detection prevents major repairs, saving costs from emergency responses and extensive rehabilitations.

- Preventive Maintenance: Proactive maintenance strategies help extend the lifespan of sewer infrastructure and ensure its reliability and service level.

The Sensors Used in Multi-Sensor Inspection

MSI employs an array of sensor technologies, each providing different types of data critical to a comprehensive sewer assessment. The integration of these technologies enables utilities to conduct thorough inspections that account for various aspects of pipeline health.

Lidar (Light Detection and Ranging)

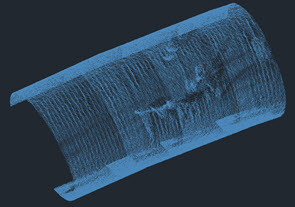

Lidar sensors offer precise distance measurements by illuminating the pipe with laser light and measuring the reflections, otherwise known as the time-of-flight principle. This technology is invaluable for detecting geometrical deformations in the sewer line, such as shape changes, deformation, corrosion, llapses, and other structural anomalies.

Photogrammetry

This technique involves capturing photographs from multiple angles and using them to make measurements and create detailed 3D models of the sewer interior. Photogrammetry is particularly useful for documenting the condition of linings and other surface characteristics that can be difficult to gauge with other sensors.

Structured Light Laser

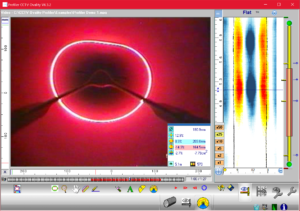

Provides accurate 2D cross sections of the pipeline through projection of a laser ring onto the wall of the pipe, the laser is in turn captured by a high resolution camera. The 2D cross sections are critical in determining Hydrogen Sulfide (H2S) corrosion levels, and deformation.

CCTV (Closed-Circuit Television)

CCTV cameras provide real-time visual feedback of the sewer interior. This direct visual inspection is essential for identifying visible issues such as cracks, joint displacements, and infiltration.

Sonar

Sonar technology is used to inspect submerged sections of sewer lines. It works by emitting sound waves and analyzing the echo to map and assess the condition of the pipe’s interior, including the accumulation of debris and sediment.

Integrating Data for Comprehensive Analysis

The power of MSI lies in its ability to integrate data from all these sensors into a cohesive analysis platform. This integration allows engineers and technicians to cross-verify information from different sources, enhancing the reliability of the assessments. For instance, what might be visible in a CCTV feed can be quantified more precisely with Lidar measurements, providing not just a confirmation of visual findings but also an exact measure of anomalies.

Fusing multiple data sources together achieves a complete picture of the pipeline. By using a fused laser/Lidar and sonar cross-section, reference information anchors to the uncorroded sonar data, ensuring accurate corrosion measurements.

MSI in Action: Real-World Applications

MSI has been successfully implemented in numerous cities worldwide, significantly improving the management of sewer assets. Municipalities have leveraged MSI to plan targeted maintenance schedules, prioritize repair budgets, and enhance the overall efficiency of their wastewater management systems. By enabling a more detailed understanding of infrastructure conditions, MSI helps cities avoid the costs and disruptions associated with sewer system failures.

Some of the notable savings have been:

- 26 Million in CIP Savings.

- 17 Million in Rehabilitation Savings – Only replacing pipe that needed to be replaced.

- 6.9 Million in Cleaning Savings – Through only cleaning pipe with debris in it.

- Forecasting CIP planning – Time based analysis allowed rate of change to be quantified.

Partnering with Industry Leaders

While multi-sensor inspection technology is advancing rapidly, the success of its implementation largely depends on expertise in both the technology and the complexities of sewer systems. For those interested in exploring MSI for their municipalities or projects, partnering with established leaders in the field can provide a significant advantage.

At RedZone Robotics, we specialize in advanced sewer inspection technologies, including multi- sensor inspection (MSI). As the pioneers in the ever changing MSI industry utilizing purpose built platforms for over 15 years, RedZone not only provides the technology but also the expertise to interpret and utilize the data effectively.

By adopting Multi-Sensor Inspection technologies, municipalities ensure efficient, future-ready sewer systems.

Take the first step towards a smarter, more resilient sewer management strategy. Partner with RedZone Robotics and set your utility on the path to success.