In the U.S., there are over 800,000 miles of public sewers. 80% of these sewers are 8″-15″, considered small diameter. These gravity sanitary and storm sewer pipes transport the majority of the most cities’ wastewater and are forced to take on increasing flow levels as new users are added to older systems. Sanitary sewer overflows (SSOs) and failures can have devastating impacts on your communities and the environment. Using small diameter inspection can pinpoint these potential failures.

Let us help you safeguard your assets by knowing what’s below.

Why inspect your small diameter pipe?

Small diameter pipes comprise a large portion of many sewer collection systems. Proper management, operation, and maintenance of these assets provides countless benefits to both the system owner and the communities served.

Smart data

Small diameter inspection collects the most crisp, clear imagery showing you the condition of your critical 8″-12″ pipes. NASSCO certified coding provides condition grading used for rehabilitation planning and maintenance.

Safer methods

SOLO is an autonomous, small diameter inspection technology that removes the risks posed by manned entry. Safety is our first priority – protecting our personnel, your community, and the environment is at the forefront of our inspection processes. Our practices keep crews safer, with longer runs and less deployments, and prevent excess traffic disruption within your local neighborhoods.

Reduced spending

Regular inspection and maintenance of your small diameter pipe increases the useful life of individual assets by identifying and prioritizing the pipes that need attention. Reduce maintenance costs by decreasing reactionary spending and identifying the assets that require proactive attention.

Sustainable practices

Shrink your Carbon Bootprint and leave less of a mark on the environment with inspect-to-clean methods. Lower your carbon emissions by 3 to 4 tons per mile of inspection over the course of a 240-mile inspection. Eliminating large box trucks and cleaning only as needed reduces emissions and water usage, saving time, money, and the world around you.

What data can be gathered from small diameter inspection?

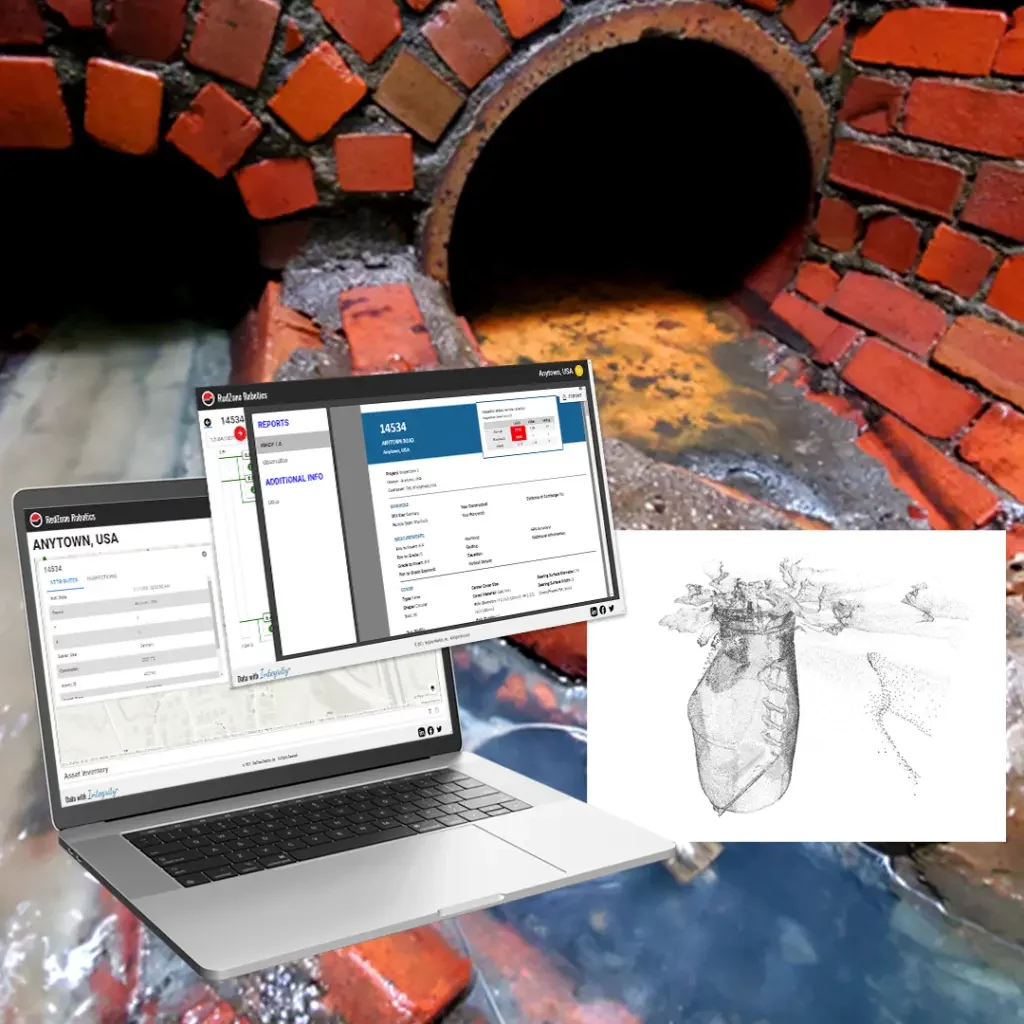

See your small diameter pipes with complete clarity with 360-degree views, high-resolution imagery, and NASSCO certified condition scoring.

NASSCO scoring

Know the condition of every asset in your system with NASSCO certified condition scoring. Rank defects by severity to understand the true condition of your system.

360° views of asset interiors

Get high resolution imagery and video of the interior of your pipe. See every defect with complete clarity using pan/tilt/zoom functionality.

Actionable management

Our data solutions provide complete, accurate reporting and interactive software tools to manage and utilize the data you receive from your inspection.

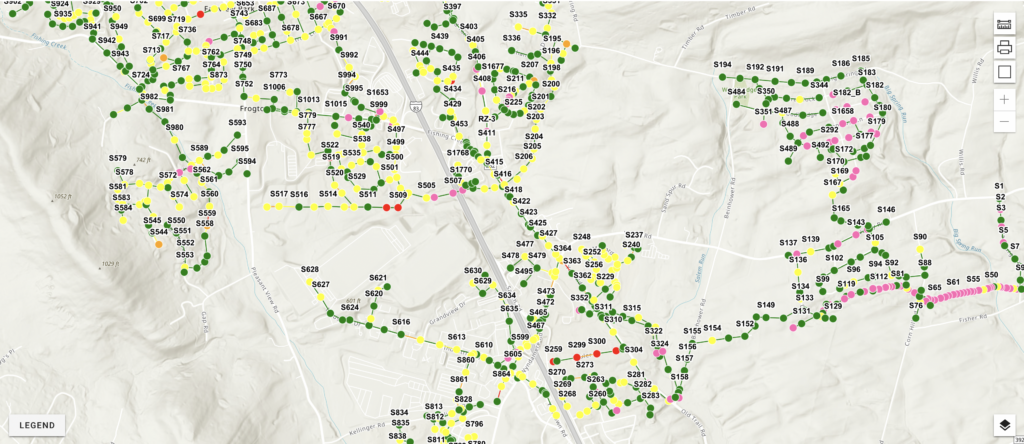

Visualize your data

Small diameter inspection provides you with an abundance of information about the state of your pipes. Interact with your data with Integrity™.

Navigate asset locations geospatially on a map, view video with pan/tilt/zoom capability, and plan for the future as you navigate actionable data.

How do I get started?

Successful small diameter inspection projects require planning and coordination. Let our skilled team of experts help you better understand the state of your system.

Getting started on your next inspection is as simple as 1, 2, 3.

- Establish what you are trying to achieve with your inspection.

Is your goal to identify defects in your pipe? Or maybe to get NASSCO certified scoring on each of your assets? Are you inspecting in order to plan for required maintenance? Whatever the reason, let us help you establish the best plan for your system. - Define the scope.

Tell us about your system. How many pipes are in your system and what size are they? Do you have accurate mapping for access shafts and manholes? Are there known issues that need addressed? When it comes to sewer inspection – we can help. - Contact us.

Fill out our contact form. One of our experienced team members will contact you to get started.

Ready to get started? Connect with us today!

Complete this form to schedule your next advanced pipeline assessment & sewer inspection, get a quote, or connect with a RedZone Robotics team member.

Want to know how RedZone Robotics helps you to reduce your CARBON BOOTPRINT? Click here to learn more!