How RedZone’s 3D Models Are Enabling the Next Generation of Sewer System Management

TL;DR

Digital twins are gaining momentum in the wastewater industry, offering powerful new ways to manage underground infrastructure. But a digital twin is only as good as the data it’s built on. RedZone Robotics doesn’t build digital twins—but it provides the foundational data that makes them possible. Tools like Profiler 3D™ and Responder™ generate precise, spatially aware models that feed directly into GIS and asset management platforms.

While full-system twins remain out of reach for many utilities, adoption is growing in targeted use cases—particularly for large-diameter pipes and critical interceptors. As data collection becomes faster and more cost-effective, utilities leveraging RedZone’s high-quality inspection data today will be well positioned to adopt more advanced digital modeling workflows tomorrow.

Introduction: The Promise of the Digital Twin

Digital twins hold incredible promise for asset-intensive industries like wastewater infrastructure. But according to Gartner, “through 2023, 80% of data and analytics projects will fail to deliver business outcomes, largely due to poor data quality and governance.” Deloitte reports that the #1 barrier to digital twin success is incomplete, inconsistent, or poorly structured data. In other words, most digital twins don’t fail because of bad modeling—they fail because the data they’re built on can’t be trusted.

That’s where RedZone makes the difference.

RedZone’s inspection platforms—Profiler 3D™ and Responder™—provide utilities with accurate, geospatially aligned, high-resolution field data that serves as the foundation for digital twin modeling. From structural geometry to surface condition to 360° video and photogrammetric modeling, RedZone delivers the reliable truth layer digital twins need to reflect the real world.

If a digital twin is a living model, RedZone provides the DNA.

RedZone’s Role: Delivering the Data That Powers Digital Twins

RedZone focuses on the inspection phase—the first and arguably most critical step in the digital twin lifecycle. With nearly two decades of experience inspecting wastewater infrastructure, RedZone delivers:

- High-fidelity 3D models of pipes and structures

- Geospatially accurate condition assessments

- Multi-sensor inspection (MSI) workflows

- GIS-compatible outputs

The result is data that meets the needs of today’s asset managers while laying the groundwork for tomorrow’s modeling initiatives.

Why Accurate Field Data Matters for Digital Twins

A true digital twin must reflect the actual condition of an asset—not just its design. That means capturing:

- Pipe geometry and dimensions

- Wall thickness and deformation

- Surface defects like corrosion or cracking

- Invert conditions and joint alignment

All of this must be linked to real-world coordinates and align with existing GIS datasets. If this information is missing, outdated, or misaligned, the resulting twin can mislead decision-makers and introduce costly risk. RedZone’s advanced tools are designed to avoid exactly that.

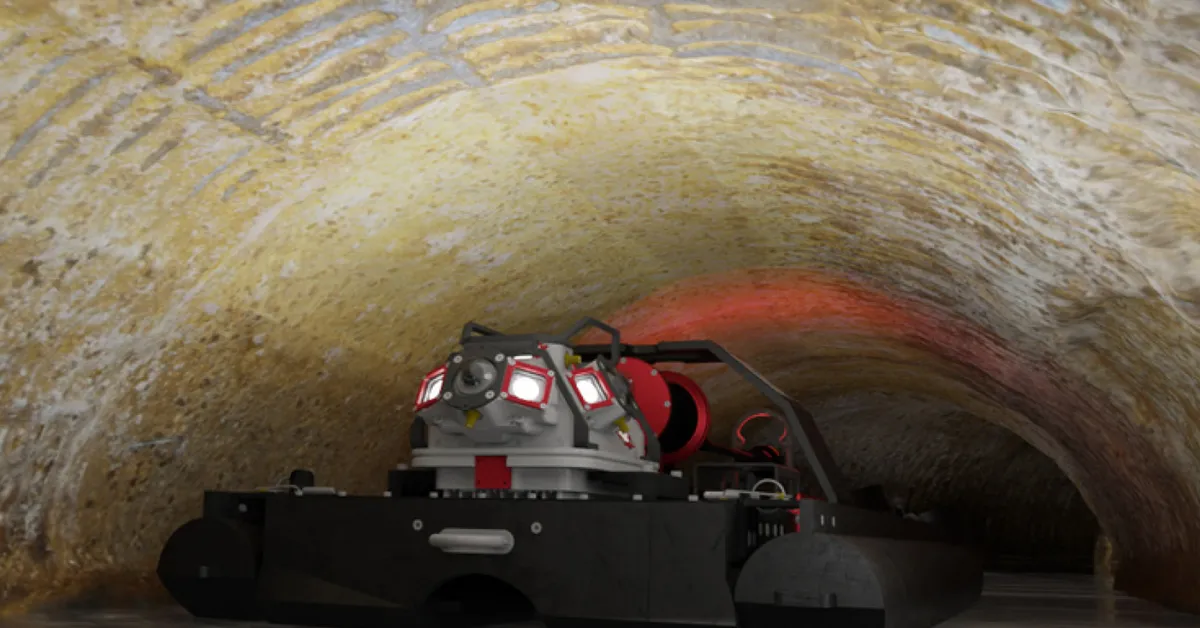

Responder™: Immersive, Spatially Aligned Visual Data

Responder™ is RedZone’s versatile mobile platform equipped with high-resolution cameras, sensors, and an Inertial Measurement Unit (IMU) for precise tracking. It enables photogrammetric 3D reconstruction and 360-degree imagery tied to real-world coordinates—ideal for walk-through visualization, training, and stakeholder engagement.

Responder’s outputs are also structured to align with NASSCO PACP standards and RedZone’s MSI framework. Its single-pass inspection workflow allows for rapid deployment with minimal disruption, even in high-flow or debris-challenged conditions.

Together, Profiler 3D and Responder provide complementary views—one geometric, one visual—that create a robust, validated baseline for digital twin applications.

Profiler 3D™: Geometric Precision at Scale

Profiler 3D™ is RedZone’s advanced floating profiling system for high-resolution inspection of large-diameter pipes. Utilizing laser technology, it captures cross-sectional measurements and deformation analysis with millimeter-level accuracy. This precision supports modeling structural conditions such as roundness, ovality, and wall thickness loss—all critical to digital twin reliability.

The system’s outputs align with NASSCO PACP standards and RedZone’s MSI framework, facilitating integration into digital twin platforms. With single-pass acquisition often completed in under 10 minutes per segment, Profiler 3D accelerates the creation of baseline 3D models for predictive analytics and capital planning.

Current Industry Adoption: Focused, Not Full Scale

While the term digital twin often evokes full-system virtualization, the reality in wastewater is more incremental. Research from the Water Research Foundation (WRF) and the American Water Works Association (AWWA) suggests that roughly 25–30% of utilities are exploring digital twin concepts, typically in limited or pilot capacities.

Rather than digitizing their entire collection system, utilities are prioritizing high-risk, high-value assets like large-diameter interceptors, siphons, and force mains. These targeted efforts are often driven by capital planning, where an accurate understanding of current pipe conditions influences millions in rehabilitation decisions.

RedZone has seen this trend across its customer base, with clients increasingly requesting high-resolution 3D data to support isolated digital twin initiatives. However, adoption remains constrained by data volume, legacy system limitations, and internal readiness. As technology improves, accurate inspection data will remain essential—and RedZone is already enabling that foundation one segment at a time.

Speed is Changing the Game

Photogrammetry and 3D modeling once took weeks. Today, RedZone’s optimized workflows allow:

- Single-pass data acquisition

- Fast photogrammetric processing

- Compressed delivery timelines

This speed makes digital twin adoption feasible not only for major cities but also for mid-sized and regional utilities. By reducing downtime and accelerating insights, RedZone lowers the barrier to entry for modern asset modeling.

Where the Data Goes: Feeding GIS and Asset Platforms

RedZone delivers data that is cleaned, structured, and ready for:

- Esri ArcGIS: for geospatial planning and visualization

- Integrity™: RedZone’s asset management platform

- CMMS and engineering platforms

This ensures inspection results become a living dataset—not a static report—that supports future modeling, predictive maintenance, and capital investment workflows.

Looking Ahead: The Future of Digital Twins in Sewer Networks

As digital tools reshape utility operations, RedZone is helping clients stay ahead. Over the next five to ten years, we expect:

1. More Predictive Maintenance Using 3D Models

Utilities will use real-world geometric data to power algorithms that forecast failure risks and recommend maintenance actions.

2. AI and Machine Learning for Interpretation

High-fidelity inspection data will feed defect recognition and anomaly detection models, enabling smarter, faster planning.

3. Focused Digital Twin Deployments

Rather than full-system twins, utilities will build dynamic models around critical interceptors, pump stations, and siphons.

4. Standardization and Interoperability

The industry will demand consistent 3D formats and shared frameworks. RedZone’s open, GIS-compatible outputs will align with this shift.

Utilities investing in detailed, spatially aligned inspection data today are setting themselves up for digital twin success tomorrow.

Conclusion: No Twin Without Truth

Digital twins may be virtual, but their usefulness depends on real-world accuracy. For buried infrastructure, field data is the only reliable source of truth.

RedZone Robotics delivers:

- High-resolution 3D inspections

- Spatial alignment to GIS

- Data formats ready for digital modeling

Whether you’re starting your first digital twin initiative or scaling an existing program, RedZone ensures your model reflects what’s really underground—from day one.

References:

- Gartner (2020) — “By 2023, 80% of data and analytics projects will fail to deliver business outcomes.” (Gartner Data & Analytics Summit; cited in Forbes & InformationWeek)

- Deloitte (2021) — “Incomplete or inaccurate data is the number one challenge in building effective digital twins.” (Deloitte Insights, *Digital Twins in Smart Infrastructure*)