At RedZone Robotics, we don’t design new technologies to replace jobs or people. Our robots are developed to solve problems that exist in the wastewater industry by making routine tasks faster and easier. More importantly, they are created to provide crucial data to help system owners make educated decisions about their systems.

Wastewater collection systems are comprised of many miles of pipe of varying sizes (or diameters). The abundance of pipe in these systems is less than 12-inches in size. These smaller-diameter pipes are the pipes that connect our houses, buildings, and neighborhoods to the larger trunk sewers. It is estimated that 70-80% of a wastewater system fits in this category of small-diameter. While larger pipes have a higher consequence of failure due to their size and flow capacity, municipal workers spend more time inspecting, cleaning, and rehabilitating these small-diameter lines due to the quantity of these lines existing in most systems.

How can SOLO make routine small-diameter inspection work faster and easier?

It all comes down to inspection data. By providing pipe condition assessment data, field crew personnel can better plan what work needs to be completed and where. Additionally, a baseline assessment of the entire system grants unique insights into planning and prioritizing this field work. However, without a large workforce and numerous camera equipment vehicles, completing a baseline assessment could take years to accomplish. This is why many system owners split this work into 5- or 10-year increments.

Time-tested performance for faster, better data

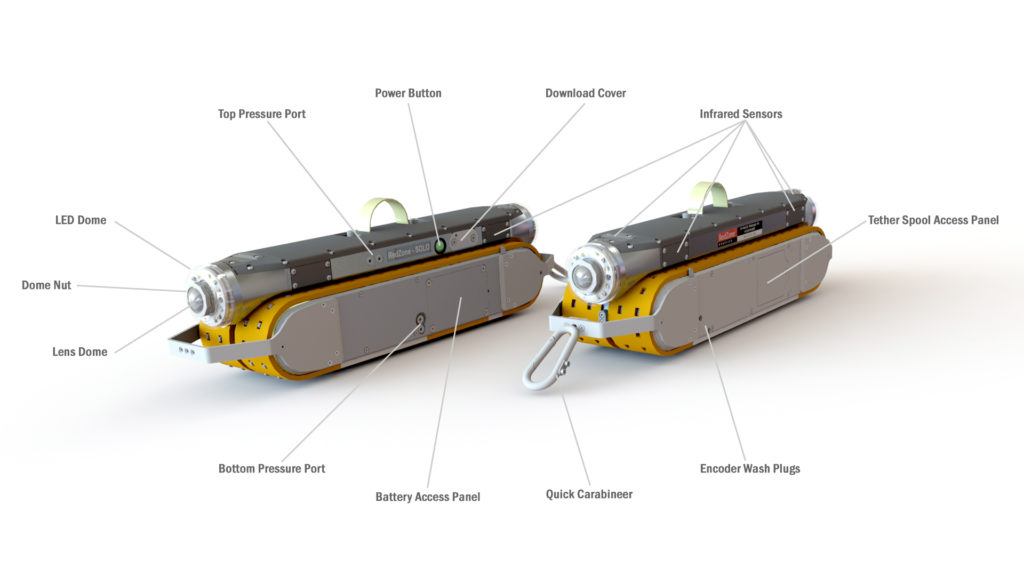

Utilizing robots we can shorten that 5-10 year time frame significantly. RedZone’s SOLO® robot was introduced in 2009 and has helped cities and municipalities to complete their inspections in a fraction of the time. This is due to its autonomy, completing inspections with minimal input from an operator. The operator is equipped with 3-4 SOLO units, allowing multiple inspections to occur at the same time. As an example, one SOLO unit could perform an upstream inspection, while another unit traverses downstream. Using these robots, field crew can collect twice the amount of footage in the same amount of time. On average, field crew personnel can collect 100,000 linear feet a month!

The SOLO unit is lightweight, allowing for easy portability for hard to reach areas such as the woods, backyards, and easements. It requires no winch or truck setup, minimizing the need for traffic control and public disruption, and creating a safer environment for field work.

Another unique feature of the SOLO is its two pano-spheric lenses, which capture 360-degree video within the pipe. This video data is digital and can be analyzed back in the office with post-processing. This frees up the operator to focus solely on inspections in the field, as opposed to the manual process of defect coding associated with conventional equipment. This also allows our team of defect coders to focus specifically on their task, producing higher quality deliverables.

Watch SOLO in action

How do I use this baseline data?

One of the struggles utilities face is insufficient data, which can make decision-making a challenge.

Where should work begin? How much cleaning is required? How do I use my limited budget?

The baseline approach answers all of these questions by providing the condition assessment details. Inspecting all of the pipes in the system allows field personnel to identify the hotspots and critical areas, as well as what pipes have no issues at all. This information is used to establish the O&M work, as well as budgets, for years to come.

One of the other key advantages to this approach is using this data to better understand system deficiencies. Typically it is assumed that all wastewater pipes need to be cleaned prior to inspection. Using the baseline assessment data from multiple systems (over 30 million feet), it was found that SOLO can traverse nearly 75% of the system in as-is condition, collecting usable CCTV data. This reduces the need and cost for cleaning lines prior to inspection, creating an immediate ROI. Saved funds can now be better spent for rehabilitation or repair for more severe issues.

SOLO’s features and its unique approach to inspection mean that a baseline assessment of a collection system is not out of reach! In most cases, the time frame can be shortened to 1-2 years to complete and system owners save money by not cleaning the entire system beforehand. With SOLO’s data, system owners can better plan routine field work, as well as preventative maintenance, for years to come.