Large-diameter sewer interceptors are critical for urban wastewater management, transporting millions of gallons daily to treatment facilities. These pipes, typically 36 to over 125 inches in diameter, are buried deep underground, often beneath busy streets or critical infrastructure, making inspections complex and costly. This article explores the challenges of large-diameter sewer interceptor inspection, how RedZone Robotics addresses these challenges with advanced technology, and why we lead the industry in the inspection of sewer interceptors.

Challenges in Large-Diameter Sewer Interceptor Inspection

1. Accessibility and Safety Risks

Inspecting large-diameter sewer interceptors is difficult due to their location. Accessing them often requires traffic control or excavation, increasing costs and community disruption. Historically, inspections involved manned entry, where workers entered the sewer to assess its condition. This method is dangerous, exposing workers to toxic hydrogen sulfide (H2S) gas, confined space hazards, and collapse risks. High flow rates—millions of gallons per day—may require bypass pumping, further raising expenses.

2. Complex Condition Assessment

These interceptors face issues like corrosion, sediment buildup, deformation, and cracking. Their size and flow volume make assessment challenging. Traditional closed-circuit television (CCTV) inspections, which rely on visual data, are limited. CCTV cannot quantify corrosion or measure debris below the waterline, leading to inaccurate assessments. Multi-sensor inspection (MSI) technology is critical for gathering comprehensive data and creating accurate condition assessments.

3. High Costs and Stakes

Large-diameter sewer interceptors are among the most expensive assets in a utility’s portfolio. A failure can release millions of gallons of sewage, causing environmental damage, public health risks, fines, and reputational harm. Inspecting or rehabilitating these interceptors can cost millions, especially if flow diversion is needed. Utilities often adopt reactive maintenance due to budget constraints, increasing long-term risks.

4. Aging Infrastructure and Technical Debt

Many large-diameter sewer interceptors, built in the early 20th century, are deteriorating. Utilities often lack sufficient data to prioritize maintenance, leading to “technical debt”—where delaying modern inspection methods increases future costs. Without accurate data, utilities may over-clean or replace pipes unnecessarily, wasting resources while neglecting critical areas.

RedZone Robotics: Leading the Inspection of Large-Diameter Sewer Interceptors

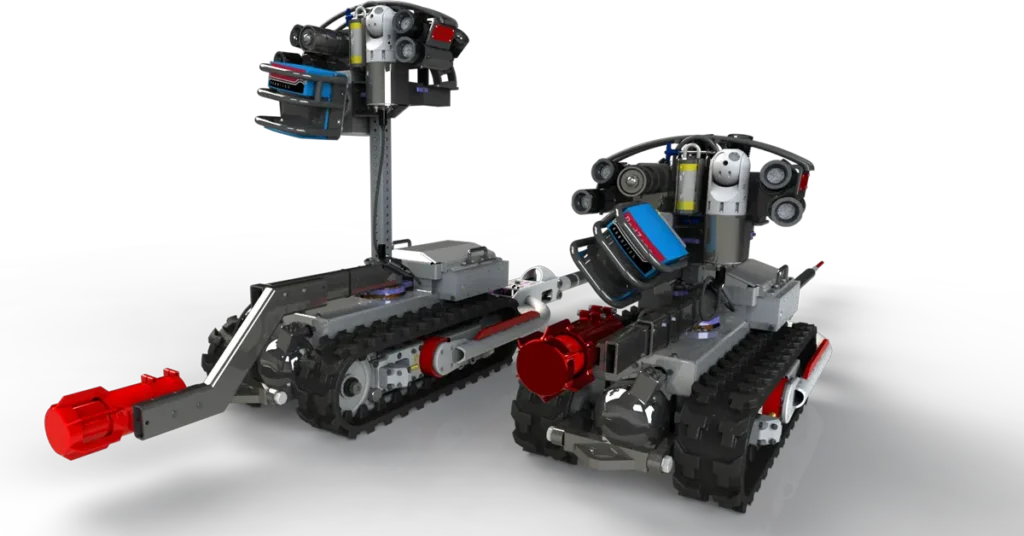

Since 1987, RedZone Robotics has been a pioneer in inspection technology. We shifted our focus to wastewater infrastructure in 2003, developing platforms specifically for the inspection of large-diameter sewer interceptors. Our Responder platform and Profiler3D technology address the unique challenges of these critical assets.

RedZone’s Innovation in Sewer Interceptor Inspection

We recognized a gap in the market for safer, more effective methods of large-diameter sewer interceptor inspection. Traditional approaches were risky and yielded limited data. We responded by creating Responder, a robotic MSI platform built for interceptors, and Profiler3D, a high-precision 3D laser profiling tool.

Our Solutions for Large-Diameter Sewer Interceptor Inspection

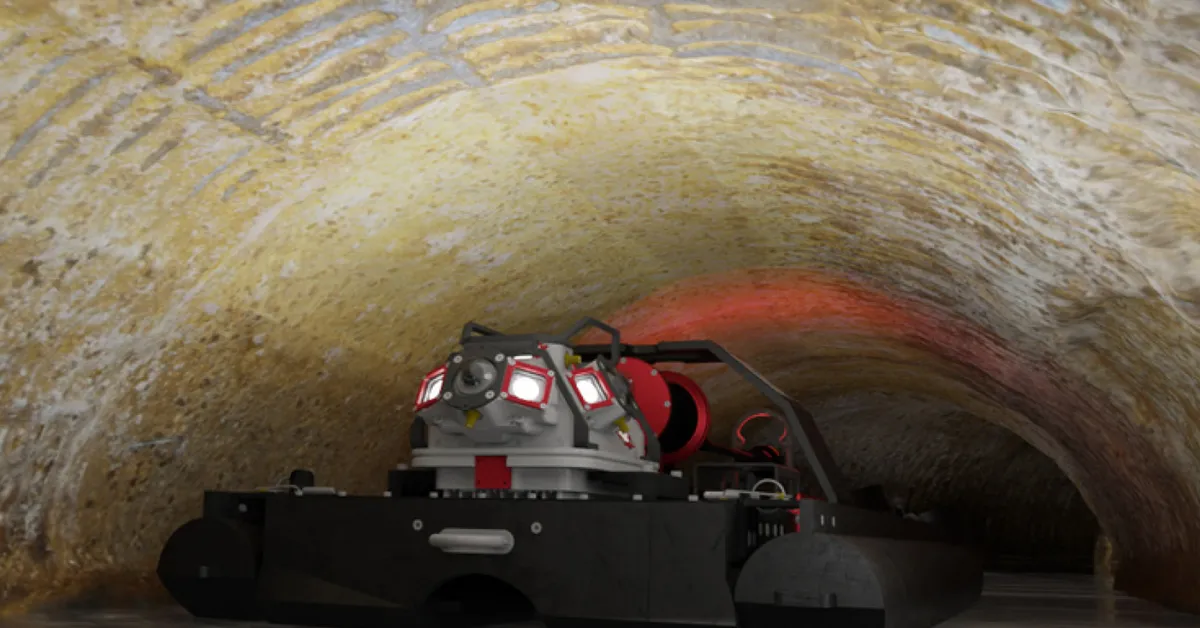

Responder: A Pioneering MSI Crawler for Interceptors

Responder was designed specifically for the inspection of sewer interceptors, capable of navigating pipes from 36 to 125+ inches in diameter. It integrates a full suite of multi-sensor inspection (MSI) tools, including:

- High-Resolution CCTV: Captures clear imagery even in low-light, high-flow conditions.

- Laser and LiDAR Profiling: Measures pipe shape, deformation, and corrosion loss with precision.

- Sonar: Maps debris and sediment below the waterline for targeted cleaning.

- Gas and Temperature Sensors: Detects hazardous conditions like H2S buildup.

- Inertial Measurement Unit (IMU): Provides 3D spatial data to verify alignment and changes in pipe structure.

Responder operates efficiently in surcharged conditions and zero air gap environments, eliminating the need for bypass pumping and minimizing operational disruptions.

Profiler3D: Advanced 3D Laser Profiling for Interceptors

Profiler3D expands our capabilities even further. Designed to capture ultra-high-resolution 3D models, Profiler3D enables municipalities to see corrosion, deformation, and wall thickness changes with photogrammetric accuracy. Profiler3D uses structured light scanning and LiDAR technology to:

- Create detailed, quantifiable 3D digital twins of sewer interceptors.

- Precisely locate and measure corrosion, cracks, and other structural anomalies.

- Document the geometry of pipes in both dry and partially surcharged conditions.

- Complement MSI data from Responder, creating a holistic view of pipeline health.

Our Profiler3D platform transforms traditional inspection data into actionable intelligence. Engineers can manipulate 3D models, pan, tilt, and zoom into problem areas, and plan rehabilitation projects with precision. By identifying defects in advance, municipalities can avoid emergency repairs and extend the useful life of their infrastructure.

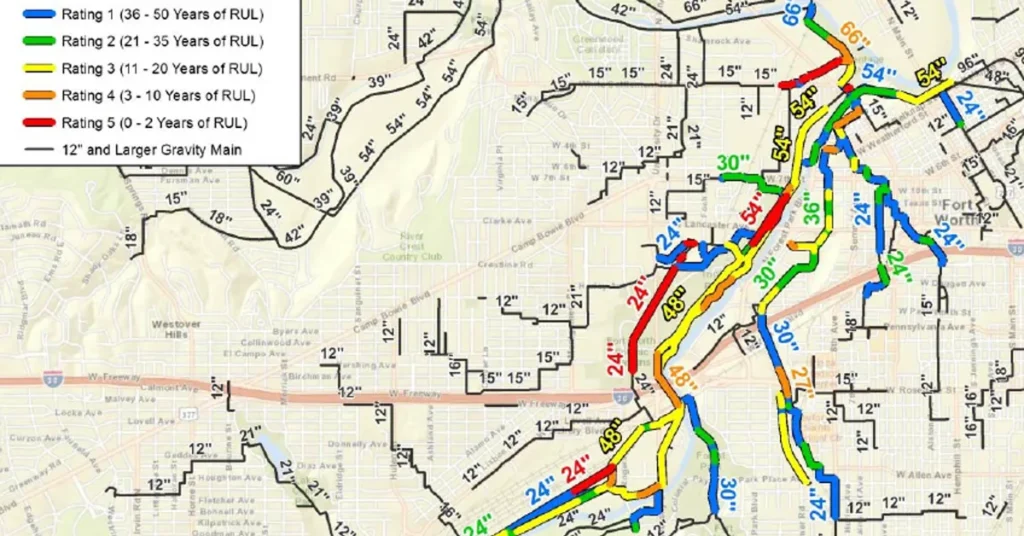

Real-World Impact: Case Study — Fort Worth Success

The Fort Worth Water Department leveraged our Responder platform for a six-year program, inspecting over 20 miles of large-diameter sewer interceptors. Using our “inspect-to-clean” approach, Fort Worth saved $2.9 million in cleaning costs by focusing efforts only where needed. Projected long-term savings over the program are estimated at $15.2 million. Profiler3D’s 3D models further helped Fort Worth quantify corrosion, optimizing rehabilitation plans and minimizing future risks.

RedZone’s Platforms vs. Other Large-Diameter Sewer Inspection Solutions

| Feature | RedZone | Other Solutions |

|---|---|---|

| Technology | Multi-sensor inspection + 3D laser profiling | CCTV-only or basic robotics |

| Data Accuracy | Empirical 3D mapping, quantifiable defects | Subjective 2D visuals |

| Flow Conditions | Operates in surcharged pipes | Often struggles with high flows |

| Safety | No manned entry, minimal disruption | May require manned entry |

| Integration | Full GIS integration (e.g., Esri ArcGIS) | Limited or no integration |

Addressing Cost Considerations for Large-Diameter Sewer Interceptor Inspection

Some utilities may wonder about the investment required for advanced inspection technologies like Responder and Profiler3D. While initial inspection costs may be higher than traditional CCTV-only surveys, the long-term financial benefits are substantial:

- Operational Savings: Our platforms eliminate the need for costly bypass pumping and manned entry operations.

- Targeted Maintenance: By identifying exactly where repairs are needed, utilities avoid unnecessary cleaning or full-system rehabilitation.

- Preventive Asset Management: Early detection of defects prevents catastrophic failures, environmental penalties, and emergency response costs.

In Fort Worth alone, the “inspect-to-clean” strategy produced a projected savings of $15.2 million—an excellent return on investment.

How We Solve Large-Diameter Sewer Inspection Challenges

Enhanced Safety

Our Responder and Profiler3D platforms eliminate the need for manned entry, keeping workers safe from H2S gas, confined space dangers, and high-flow conditions. We minimize community disruption by avoiding bypass pumping and excavation.

Comprehensive Data for Informed Decisions

We deliver 360-degree, multi-sensor inspection (MSI) datasets combined with high-fidelity 3D laser profiles. Our data integrates seamlessly with GIS systems like Esri ArcGIS, allowing utilities to prioritize repairs based on empirical evidence, not guesswork.

Cost Savings and Reduced Technical Debt

Our approach cuts operational costs while reducing technical debt. Utilities save money by targeting cleaning efforts, avoiding unnecessary maintenance, and developing proactive capital improvement plans based on real data.

Support for Aging Infrastructure

By providing accurate, actionable insights, we help utilities extend the life of aging sewer interceptors, reduce regulatory compliance risks, and allocate limited resources where they will have the most impact.

The Future of Large-Diameter Sewer Interceptor Inspection

At RedZone, we continue to innovate. Our future developments will include:

- Artificial Intelligence: Predictive analytics for maintenance recommendations.

- Digital Twins: Full 3D models of sewer networks for advanced planning.

- Real-Time Data Streaming: Immediate defect detection during inspections.

These innovations will further enhance how utilities inspect, maintain, and protect their large-diameter sewer interceptors.

RedZone Robotics leads the inspection of sewer interceptors by addressing challenges related to safety, data accuracy, operational costs, and aging infrastructure. Our multi-sensor inspection (MSI) technology, combined with Profiler3D laser profiling, provides utilities with unparalleled insights.

For municipalities managing critical wastewater infrastructure, RedZone offers the expertise, technology, and support needed to make proactive, data-driven decisions.

Ready to Inspect Your Interceptors?

Schedule a Responder demo or request a quote today. Discover how we can help you protect your most valuable sewer assets while reducing costs and improving system reliability.