Some of the most critical pieces of infrastructure are large diameter pipes as these linear assets carry large amounts of flow and sewage to treatment facilities. Failure is not an option, so organizations must perform their due diligence regarding the current state of the infrastructure. This includes an analysis of the condition, shape and size changes, access points and alignment, as well as hydraulic capacity. This initial step ensures that any design, planning, and pre-construction phases for rehabilitation will be effective and efficient. Fortunately, all of these data points can be gathered through a single Multi-Sensor Inspection (MSI) – a combination of CCTV, sonar, and laser data.

Laser-based inspection compliments the collected CCTV footage, since lasers can better detect the changes in pipe shape caused by corrosion, deterioration, deformation, and deflection. Typically, de-watering is required for pipe rehab. De-watering provides the perfect opportunity to gather significant amounts of the pipe interior with laser inspection, as lasers cannot collect data below the flow. The primary laser type used for this analysis is called LiDAR: Light Detection and Ranging.

Why LiDAR Inspection?

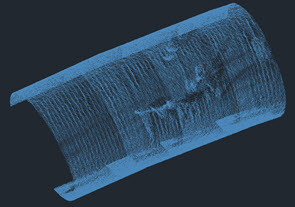

LiDAR uses the time-of-flight (ToF) principle to record reflected laser light in order to determine distance. These measurements are used to create point cloud models from the scan which display the internal shape of a pipe section.

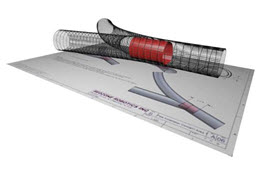

These point cloud scans are aligned using noticeable features in the laser data: joints, taps and laterals, key defects and deterioration. These overlapping scans also provide numerous data points for accurate measurements. Once the section of pipe from manhole to manhole has been assembled and analyzed, the manholes are virtually aligned to “real-world” structures by utilizing survey-grade GPS coordinates. This provides an understanding of the alignment of the sewer in relation to above-ground structures.

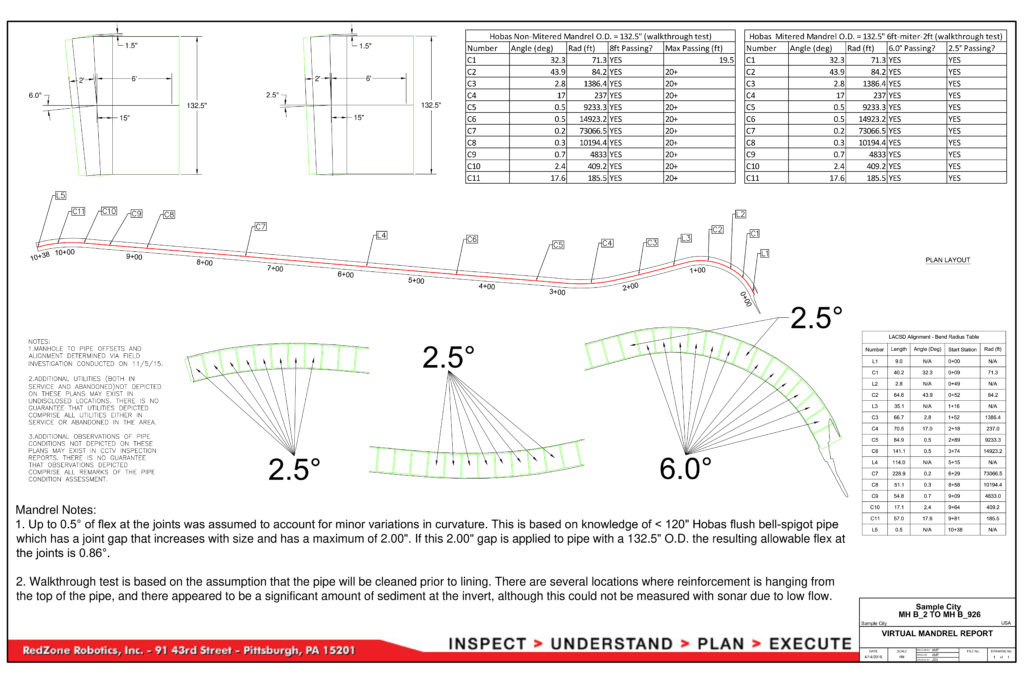

This newly completed alignment model is ready for data measurements. Known as bend analysis, this step provides crucial information about the deflection of pipe segments in all directions. Bend analysis also provides the curvature and radius of those bends, typically along the center line. Cross-sectional measurements then confirm the internal diameter (ID) of the pipe at any location where laser data was collected. Powered by both pieces of information, a mandrel test can be simulated.

Virtual Mandrel – Data for Design

A mandrel test is the process of evaluating for obstructions of a structure compared to a specific size. These obstructions could be ovality, deformation, or debris. Mandrel testing is used prior to rehabilitation to determine the design specifications required. This prevents a liner from becoming ‘stuck’ on an obstruction within the host pipe during the construction process, and ensures proper conformity post-construction. The virtual mandrel applies this same concept through technology-aided simulations. More importantly, this removes the risk of damaging the pipe with the placement of a physical mandrel.

The report produced from this testing can be run at numerous sizes, often in coordination with a manufacturer’s liner specifications. This includes not only testing the outer diameter (OD) of the liner, as mentioned above, but the deflection and curvature of the liner based on how it maneuvers through bends. Often times, this results in custom length liners to fit the curvature of the host pipe.

Can My Rehab Project Benefit from Virtual Mandrel or Bend Radius Analysis?

There are many ways to mitigate potential failure and extend the useful life of pipe infrastructure. Cured-In-Place Pipe lining (CIPP), Fiberglass Reinforced Pipe slip-lining (FRP), and geopolymer coatings are the more common methods. The value of a proper multi-sensor investigation cannot go understated. It informs the variable conditions of the pipe, the design specifications and proper compliance for the rehabilitated section.

Quantifying the true state of the pipeline with clear and concise laser data empowers an engineer or system owner to make data-driven decisions about the appropriate rehab process. It also streamlines the numerous phases to keep the project on time and on budget, ultimately increasing your ROI.