Meet the Profiler® MSI Pipe Inspection Float family.

The team of profiling tools that can meet all of you wastewater infrastructure inspection needs.

SuperMD Profiler®

Designed for interceptors

Laser/sonar profiling

Wide-angle video

Long distance deployments

MDProfiler®

Designed for mid-sized pipes with or without flow

Laser/sonar profiling

Long distance deployments

SnapOn Profiler®

Designed to enhance existing crawler platforms

Ovality measurement

Data management software

Why Profiler®?

The adaptable, accurate multi-sensor monitoring solution for almost any pipe.

- Adaptable

The Profiler® MSI Pipe Inspection Float is adaptable for an abundance of pipe sizes with and without flow. - Long range

Conventional sonar platforms require a cable to the surface to control the equipment in the pipe. Due to the modular recording components stored within Profiler® MSI Pipe Inspection Float, inspections are only limited by the battery life of the unit, allowing for long stretches of line to be easily inspected. - Siphons

Inspect siphons and fully surcharged lines to identify the true condition of your pipes. - Accuracy

Accurate, precision assessment with accuracy of +/- 3 mm – 24mm (.12 in – .9 in) dependent on Profiler platform and conditions.

Check out Profiler 3D™, our newest technology in the Profiler family

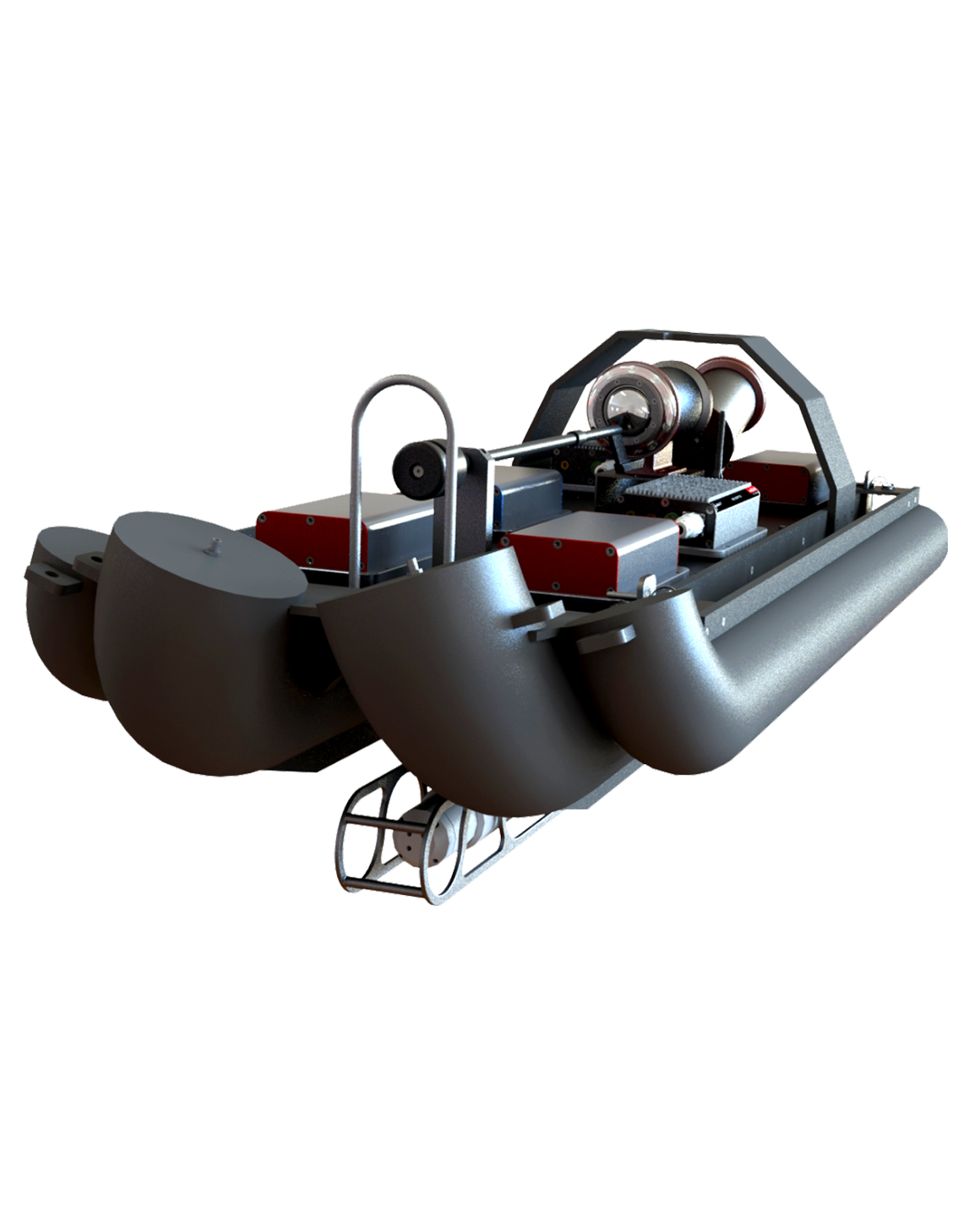

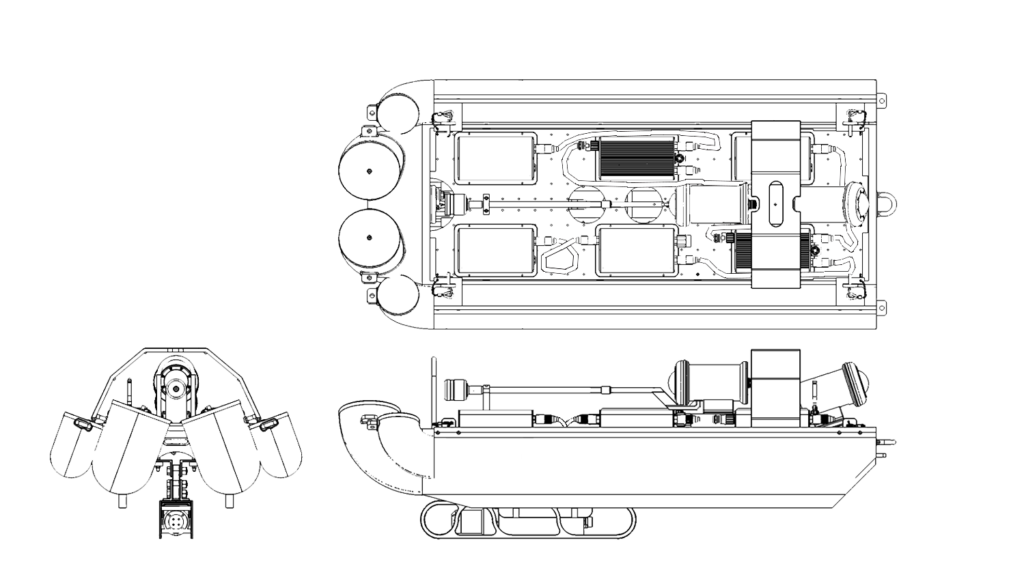

SuperMD Profiler®

Designed to traverse interceptors and other hard-to-reach assets that most conventional crawlers cannot, SuperMD is the perfect choice for long distance deployments of 10,000 feet (3,000 meters) or more, providing laser and sonar profiling with high-resolution virtual pan, tilt, and zoom camera.

Proactively protect interceptors

Interceptors are some of the most difficult areas of a system to access and are often the backbone of any city’s sewer infrastructure. They are also the most expensive to clean, maintain, and rehabilitate and present the highest consequence of failure within any system. With SuperMD Profiler®, you get the clearest picture of your system’s interceptors that no crawler can provide.

Deliverables

Corrosion, Debris, Flow Height, Pipe Size, Ovality

Platform Specs

Sensors

Laser, Sonar, CCTV- Virtual Pan/Tilt/Zoom

Parameters

Transportation: Floating platform

Pipe Size: 36-125 in (915-3200 mm)

Min. Flow: 15 in (380 mm)

Min. Air Gap: 20 in (500 mm)

WiFi Connectivity: Dependent on pipeline conditions

Contact us to learn how SuperMD Profiler can gather multi-sensor data for your system.

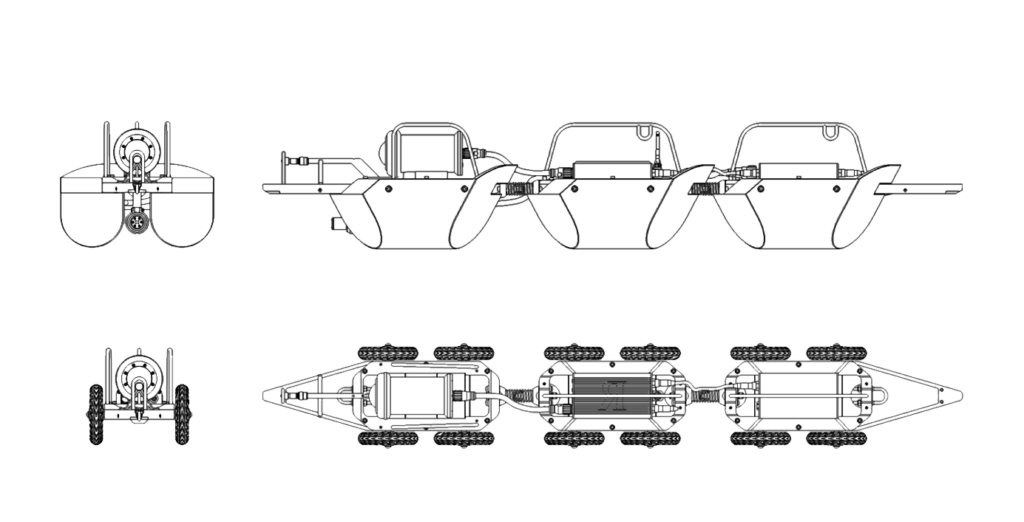

MDProfiler®

Designed to gather a full spectrum of MSI inspection data including CCTV, sonar, and laser data, MDProfiler is designed for long distance deployments of 10,000 feet (3,000 meters) or more.

Mid-Sized MSI

MDProfiler’s adaptable design allows for both wheeled or float platforms in order to gather the most data possible within your mid-sized pipes. Flow or no flow – not a problem for the MDProfiler.

Deliverables

Corrosion, Debris, Flow Height, Pipe Size, Ovality

Platform Specs

Sensors

Laser, Sonar, CCTV – Virtual pan, tilt, and zoom

Parameters

Transportation: Floating/wheeled platform

Pipe Size: 20 – 36 in (500-915 mm)

Min Flow: No flow

Min Air Gap: 8 in (200 mm)

WiFi Connectivity: Dependent on pipeline conditions

Contact us to learn how an inspection with MDProfiler® can help protect your system.

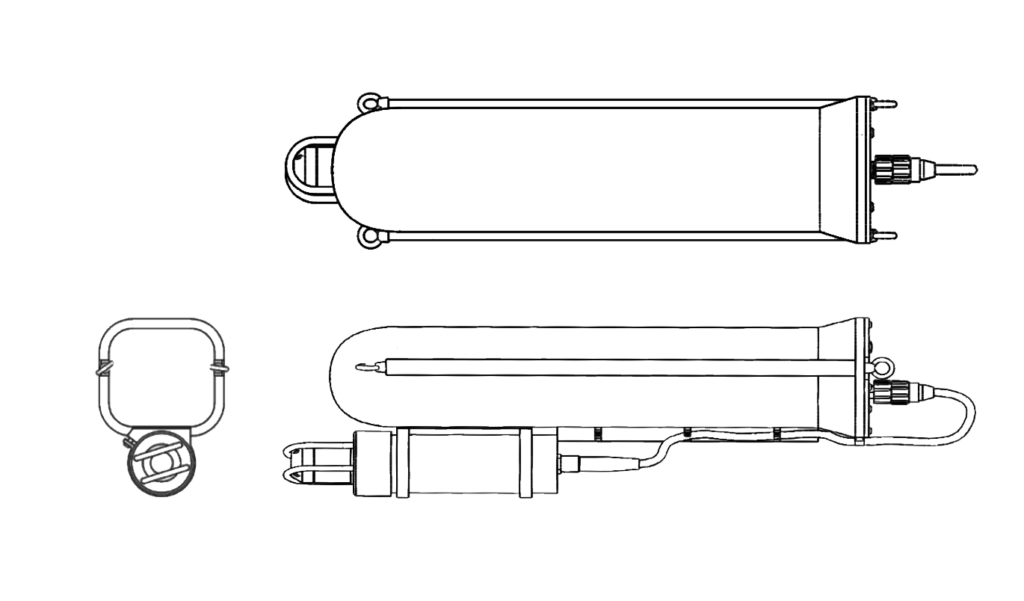

MDSub®

Designed for siphons and fully surcharged lines, MDSub allows for long-range deployments of 8,000 feet (2400 meters) or more. Identify areas of significant sediment build up in those hard-to-reach places where no CCTV crawler can go.

Mid-sized MSI

MDSub allows you to identify the true condition of your surcharged assets including major faults, debris volume and location, and water level.

Deliverables

Debris, Flow Height, Pipe Size

Platform Specs

Sensors

Sonar

Parameters

Transportation: Neutrally buoyant platform

Pipe Size: 20-87 in (500-2200 mm)

Min. Flow: 14 in (350 mm)

Min. Air Gap: 0 in (0 mm) (Fully surcharged)

Contact us to learn how MDSub can gather robust sensor data in your mid-sized pipes.

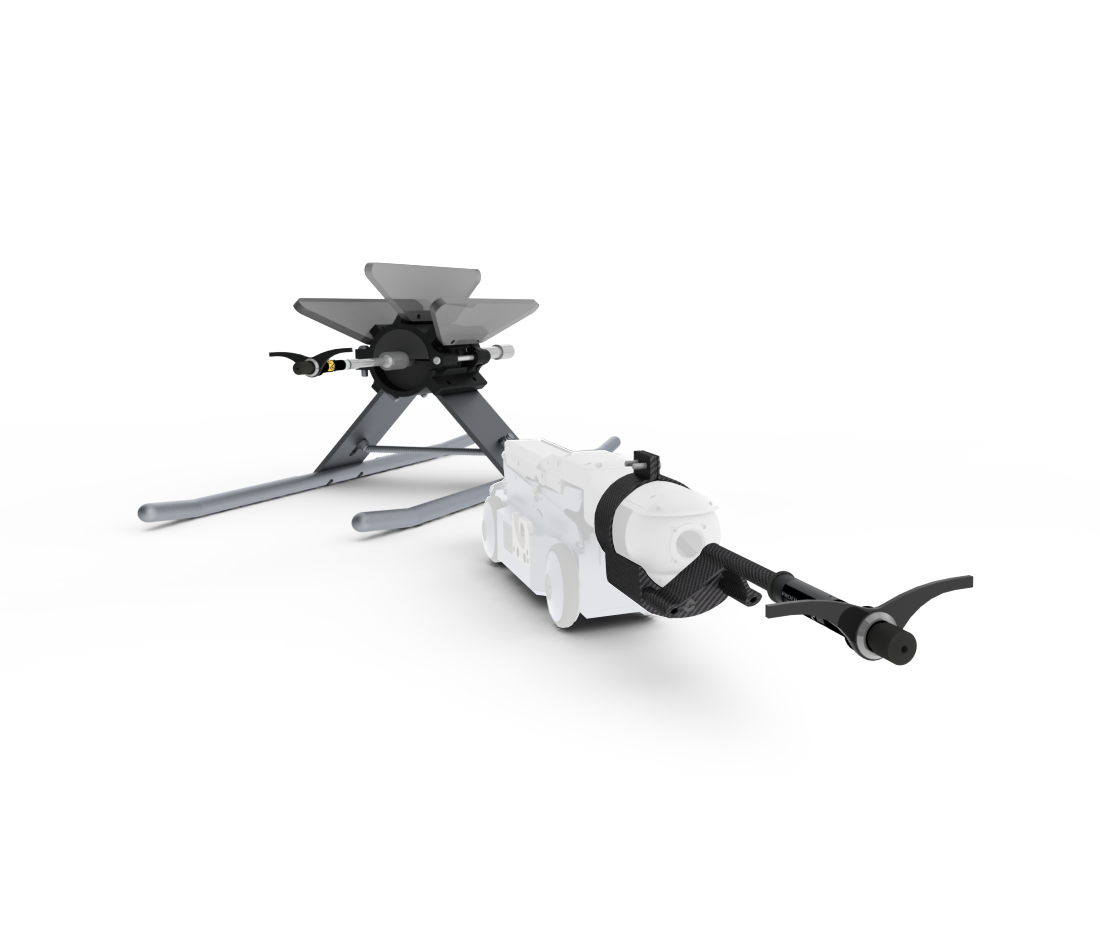

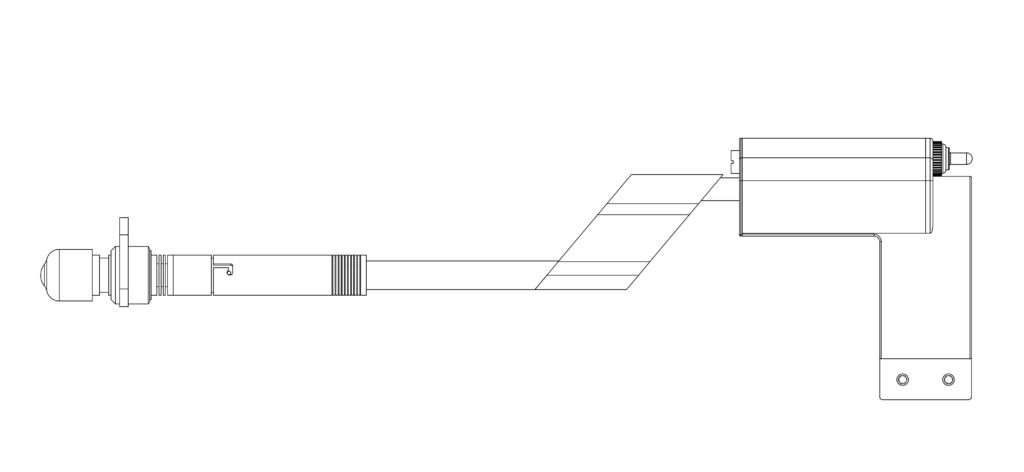

SnapOn Profiler®

SnapOn lasers provide ovality profiling measurements to enhance the information gathered by many of the most popular CCTV cameras. Simply attach the laser to the crawler and craweler’s camera will collect and record the laser projected on the pipe wall. The SnapOn software then digitizes the pipeline condition, presenting the previously unseen, unquantifiable deformation in easy-to-read reports.

Universally Compatible

With over 500 systems sold in 43 countries, RedZone’s SnapOn lasers attach to most industry leading CCTV cameras and the deployment software has been translated into 10 languages.

Deliverables

User Generated Reports including Ovality Line Graph, Topographical Flat Graph, Median Diameter, Min/Max Diameter, True Diameter, Capacity

Exports – CSV, STL

Compatibility Specifications

CUES – Datasheet

IBAK – Datasheet

iPEK/Envirosight – Datasheet

Subsite/RSTechnical

Software

Full Install – 6.3.2 – Download

Contact us to learn how SnapOn Profiler can add ovality profiling capability to your inspection tools.

Ready to get started? Connect with us today!

Complete this form to schedule your next advanced pipeline assessment & sewer inspection, get a quote, or connect with a RedZone Robotics team member.

Want to know how RedZone Robotics helps you to reduce your CARBON BOOTPRINT? Click here to learn more!