The varying conditions within a pipeline play a crucial, and often limiting, role during CCTV inspections. The biggest effect on quality CCTV? Flow levels. A CCTV camera provides little useful data when used underwater. So how do you get the most accurate and valuable data when assessing pipes with flow? Hint: Sonar inspections.

Assessing pipes with flow using Sonar

Sonar stands for Sound Navigation and Ranging. Sonar determines the location of a surface by calculating the time required for a sound wave to reflect off the surface and back to the sensor. This same skill is often associated with members of the animal kingdom, like whales and bats. Similar to how these animals determine their surroundings, sonar can be effectively harnessed and applied to the wastewater environment.

Understanding how profiling sonar works

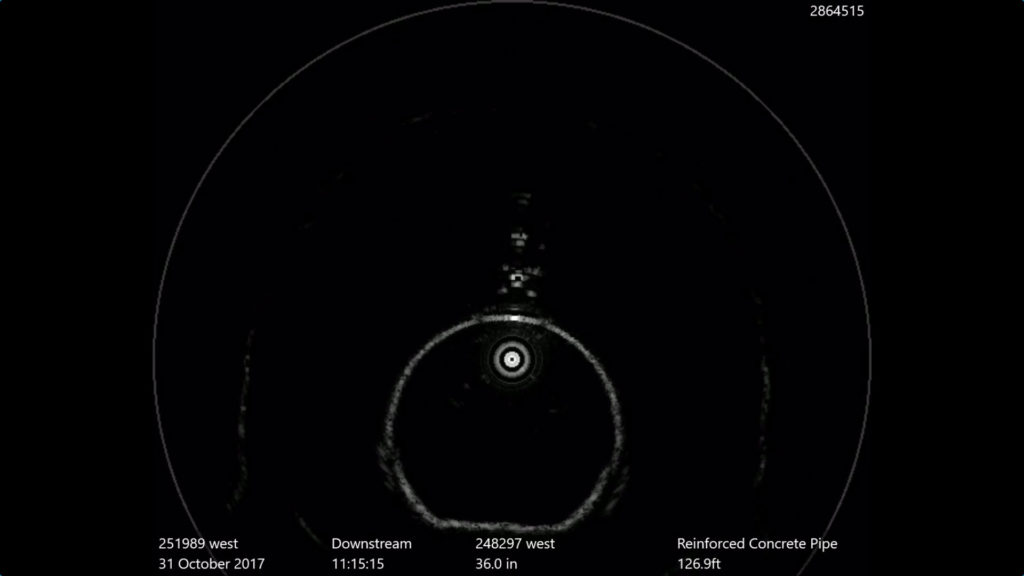

Profiling sonar units are most commonly used in wastewater assessment. These units use a single transducer mounted to a crawler or floating platform, that rotates as the transport moves through the pipe. This rotation creates a cross-sectional image of the internal diameter (ID) of the pipe, as seen in the video below. Since the sonar unit is attached to the transport, the scans are linked to the chainage, or linear distance, associated with the tether. This allows for easy identification of the unit’s location in the pipe.

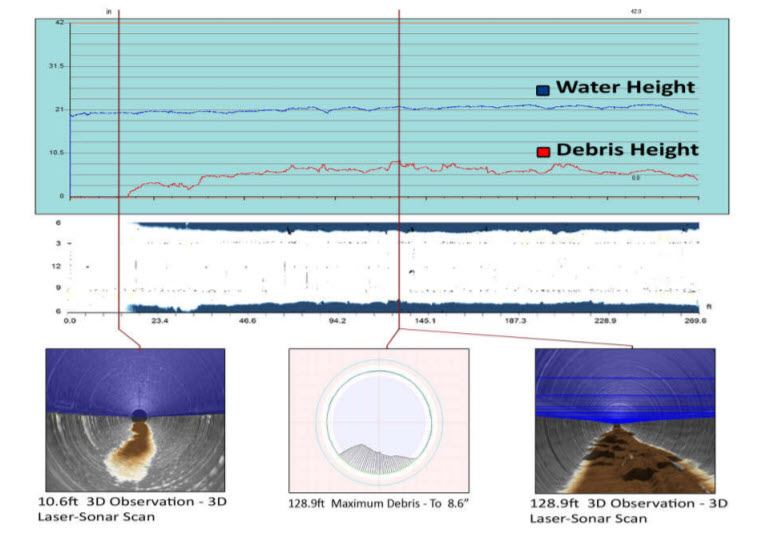

These cross-sections capture the conditions of the walls and inverts of the line below the flow. More importantly, when compared to the expected diameter of the pipe, it can quantify the measurements and deviations. This provides a comprehensive and accurate analysis of the pipe condition below the flow as corrosion (measurements larger than expected ID) or build-up and debris (measurements smaller than ID). This data is used to answer crucial questions about a system:

- What is the average depth of the sediment and debris?

- What is the cumulative volume and distribution of sediment and debris?

- How much hydraulic capacity am I losing?

How to inspect siphons or submerged lines?

Fully submerged lines pose a unique and often difficult task for assessment or maintenance crews. Many operators lack the experience or equipment to perform these inspections properly, adding to the risk of the unknown. Siphons, for example, divert gravity flows beneath rivers, railroads, and other infrastructure, resulting in a pressurized, and fully submerged, section of conveyance within the line. CCTV equipment struggles with the increase in slope and the lack of visibility.

Fortunately, sonar thrives in this environment. A sonar sensor is able to successfully navigate the contours of the siphon and provide the cross-section for the entire circumference of the pipe, detecting any size, shape, or other geometry changes along the way.

Which leads us to the question on every organization’s mind…

“Am I cleaning the right lines? Will I exceed my budget?!”

Many system owners spend a large portion of their budget on the operation and maintenance of their pipes, with a significant focus on cleaning and jetting. The assumption is that every wastewater pipe requires cleaning. Sonar inspections can eliminate the guesswork and uncertainty that exists with these tasks in mid to large diameter lines.

Quantifying the debris also eliminates the ambiguity that exists within cleaning proposals and public bids. The budget requirements are defined by the sonar data results. As an example, a pipe with a known sediment volume is easier to estimate the cleaning, removal, and hauling of the sediment than one that was never inspected.

Additionally, post-cleaning sonar inspections are a great resource tool. With any contractor work, it is important to verify the work performed. Post-cleaning sonar assessments can be compared to pre-cleaning inspections to estimate the amount of material removed. This ensures alignment with the specifications and that system owners get what they pay for!

Continued, routine sonar inspections determine changes in pipe ovality, deterioration, and debris levels, providing crucial information prior to any catastrophic failure. Don’t let high flows stop you from determining what you need to know!

RedZone offers sonar on many of our inspection units including Responder, MD Sub, MD Profiler, and SuperMD Profiler.